Project: Material Handling Machines for Bourbon Barrel Cooperages

NEED A SIMILAR APPLICATION QUOTED?

GIVE A CALL TODAY 812-618-5089 FOR QUOTE!

CHALLENGE

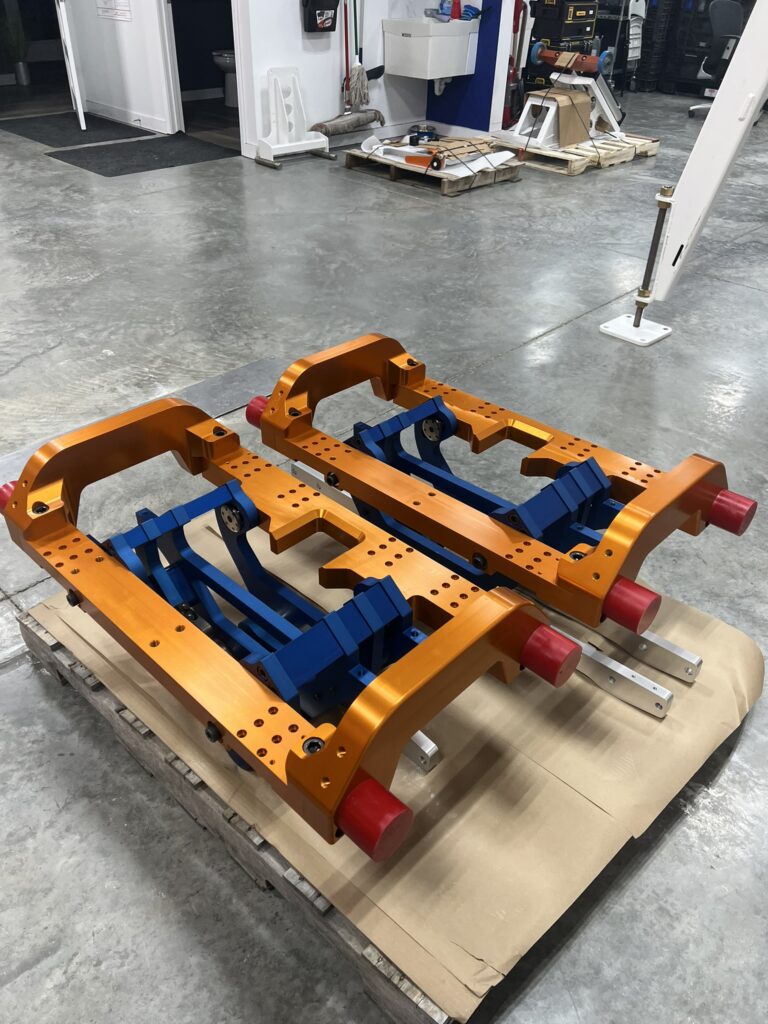

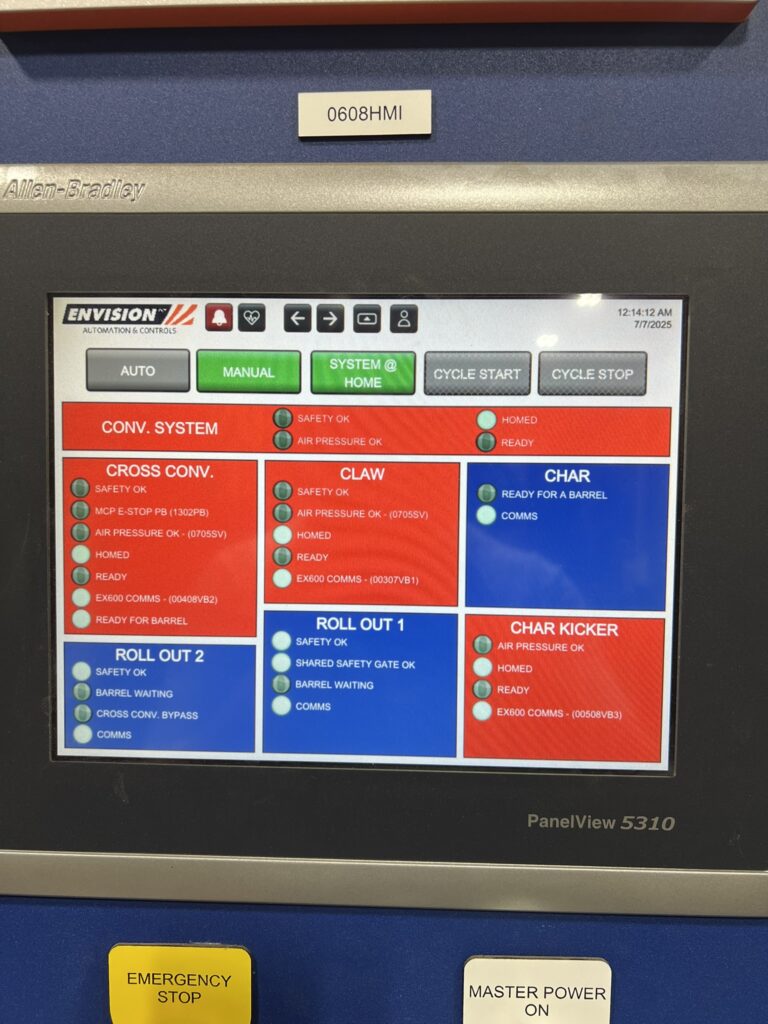

Our customer (A Bourbon Cooperage) was looking to expand their capacity at two of their cooperages. We provided two systems in total, one for each Cooperage. This system needed to combine the output of two automated Roll Out machines into one automated Char system. In total we built two machines (Per Plant) and integrated 4 systems to communicate over Ethernet/IP and CIP Safety. Our Cross Conv. and Claw (Pick & Place) would act as the heart of these systems. Handling priority from either Roll Out line as well as traffic control into the Char system.

SOLUTION

Envision Automation & Controls designed, built, and integrated this machine for the specific application using the follow steps:

Our Process:

- Discovery

- Conception

- Proposal

- Kickoff

- Mechanical, Electrical, and Pneumatic Engineering

- Machining/Fabrication

- Assembly

- Programming

- Run-Off

RESULTS

Project Overview:

- Project Type: Turnkey

- Cycle Time: 30s

- Application: Material Handling

These machines and integrations allow our customer to deliver on their promise as a supplier to deliver bourbon barrels.

FEATURES

- 480VAC

- Encoded Position Control

- Servo Motion Control

- Pick & Place

- Traffic Control

- Ethernet/IP Comms

- CIP Safety

- Conveyor Part Accumulation

SAFETY

- E-Stop Pushbutton

- Door Interlocks

- LOTO Disconnect

- Machine-To-Machine Safety Integration

MAJOR COMPONENTS

- Custom Conveyor

- Custom Barrel Receiver

- Custom Pick & Place

- Custom Barrel Kicker

- Control Panels

SERVICES

- Mechanical Design

- Fabrication/Machining

- Electrical Design

- PLC, HMI, & Servo Programming

- Installation

- Multi-Machine Integration