Project: Down Ender for Bourbon Barrel Cooperage

NEED A SIMILAR APPLICATION QUOTED?

GIVE A CALL TODAY 812-618-5089 FOR QUOTE!

CHALLENGE

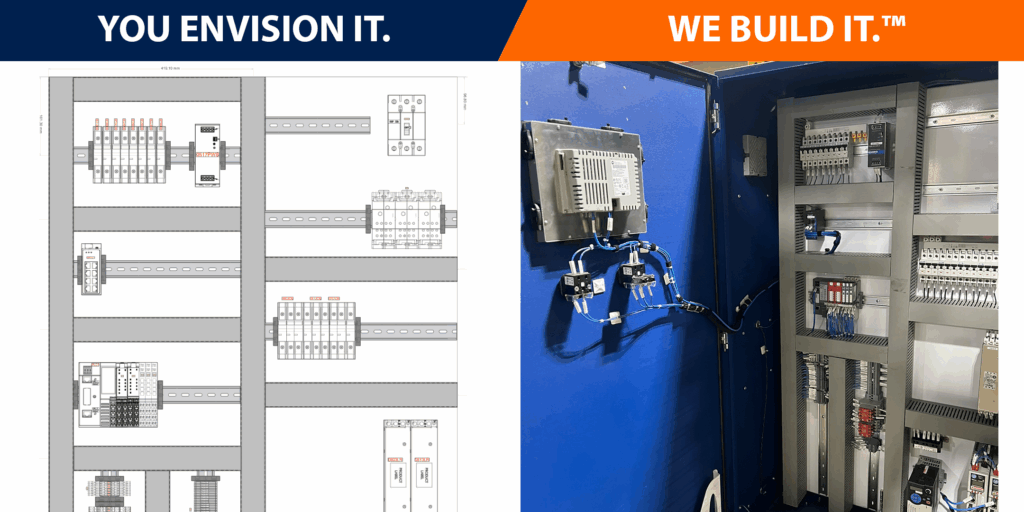

Our customer (A Bourbon Cooperage) was looking to expand their capacity at two of their cooperages. As part of that expansion a Down Ender was built and provided by another vendor less the controls package and hardware. We provided a complete set of drawings, PLC, HMI, Servo Programming. We also field wired the equipment to our control panel designed and built in-house. This Down Ender integrated with upstream and downstream equipment over Ethernet/IP Comms. Envision Automation & Controls also provided integration services of the upstream accumulation conveyor and diverters. This allowed the outfeed of the toast system to prioritize and send barrels to the appropriate Roll Out machines based on production needs.

SOLUTION

Envision Automation & Controls designed, built, and integrated this machine for the specific application using the follow steps:

Our Process:

- Discovery

- Conception

- Proposal

- Kickoff

- Mechanical, Electrical, and Pneumatic Engineering

- Machining/Fabrication

- Assembly

- Programming

- Run-Off

RESULTS

Project Overview:

- Lead Time: 6 Wks

- Project Type: Controls Integration

- Cycle Time: 15s

- Application: Material Handling

These machines and integrations allow our customer to deliver on their promise as a supplier to deliver bourbon barrels.

FEATURES

- 480VAC

- Servo Motion Control

- Upstream/Downstream Comms

- Ethernet/IP Comms

SAFETY

- E-Stop Pushbutton

- Door Interlocks

- LOTO Disconnect

MAJOR COMPONENTS

- Control Panel

- Wireway

- Field Hardware

SERVICES

- Electrical Design

- PLC, HMI, & Servo Programming

- Installation

- Multi-Machine Integration