Project: Leak Test Machine For Tier 1 Automotive Supplier

NEED A SIMILAR APPLICATION QUOTED?

GIVE A CALL TODAY 812-618-5089 FOR QUOTE!

CHALLENGE

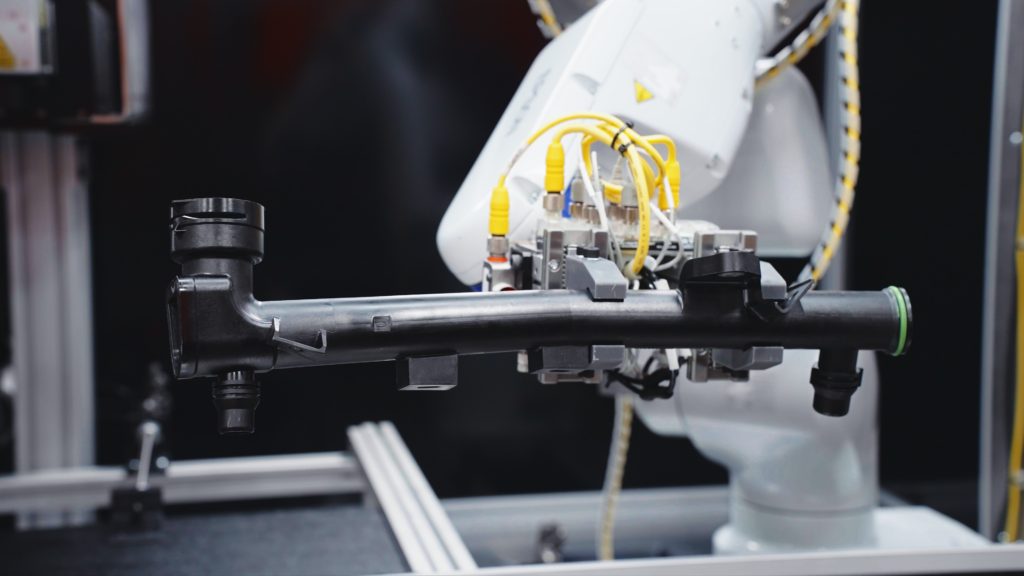

Our customer (Tier 1 Automotive Supplier) was awarded a contract by an auto maker to produce a plastic part. This part needed to be leak tested as it would be used in within the coolant system. Along with the leak test, the part also needed light duty assembly, laser marking, data collection, and part sortation. Tooling would be toolless quick-change with tooling I.D. for future proofing the machine for model variants. This would give the manufacturer the confidence in knowing their parts conform to their customers’ specifications. This project was requested by the customer to be turnkey.

SOLUTION

Envision Automation & Controls designed, built, and integrated this machine for the specific application using the follow steps:

Our Process:

- Discovery

- Conception

- Proposal

- Kickoff

- Mechanical, Electrical, and Pneumatic Engineering

- Machining/Fabrication

- Assembly

- Programming

- Run-Off

RESULTS

Project Overview:

- Lead Time: 18 WKS

- Project Type: Turnkey

- Nest: 1 UP

- Cycle Time: 60s

- Application: Leak Test

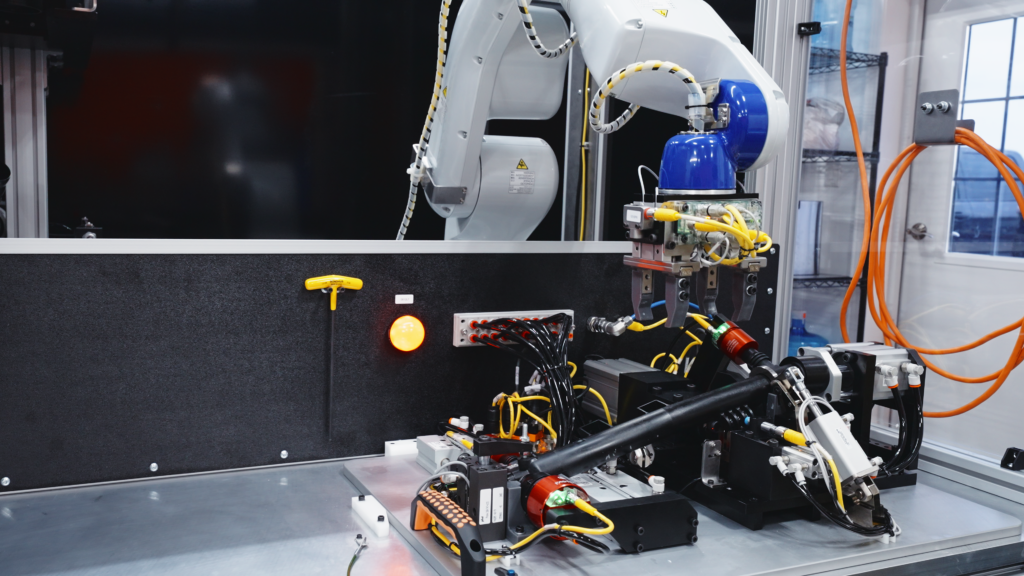

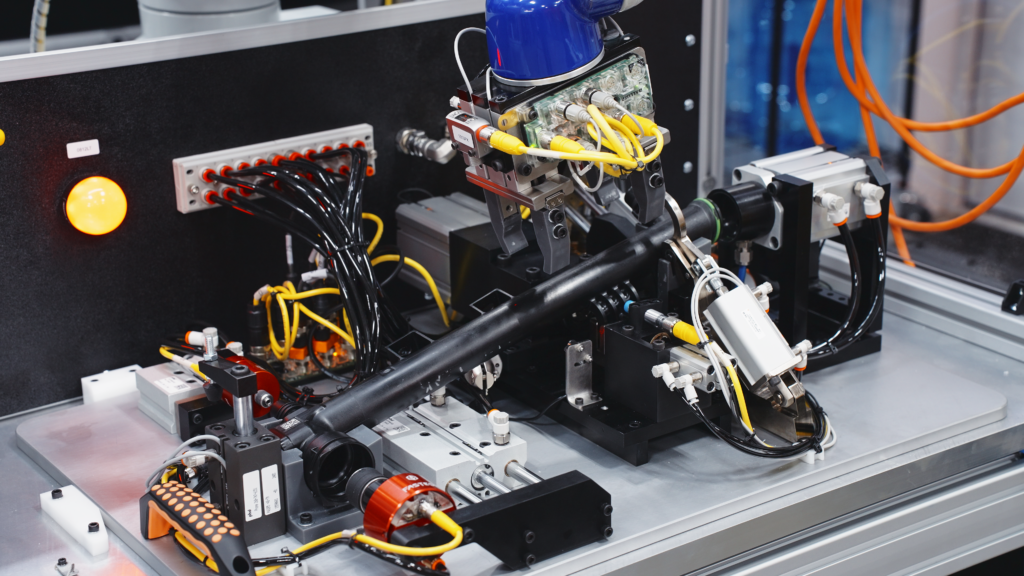

The 18 week project resulted in a turnkey machine that runs cycles under 60s and allows Zone 1 (Tooling) to be loaded by an operator while Zone 2 (Robot/Laser) is laser marking, sorting parts based on the leak test performed in Zone 1. The intuitive HMI interface allows for easy operation/diagnosis of the machine at a glance. The leveling casters allow for the machine to be easily positioned and leveled. The guarding allows for easy access to critical areas of the machine for maintenance and troubleshooting. The robot pendant mount ensures no damage to the robot pendant while not in use. The integrated laser monitor and keyboard gives instant access to laser marking profiles. The reject bin is housed behind an interlocked door so that failed parts may be collected by an operator/supervisor.

This machine allows our customer to deliver on their promise as a supplier to deliver quality and leak free parts.

FEATURES

- Leak Test

- Robot Pick & Place

- Assembly

- Laser Marking

- Mark Verification

- Test Data Collection (Traceability)

- Part Sortation (Conveyor = Pass / Reject Bin = Fail)

- Conveyor Part Accumulation

- Tooling I.D.

- Quick-Change Tooling (5 Min.)

- Fume Extraction

- 120VAC

SAFETY

- Dual Zone Control & Interlocks

- Automated Robot Recovery

- E-Stop Pushbutton

- Light Curtains

- Door Interlocks

- Guarding

- LOTO Disconnect

MAJOR COMPONENTS

- 6 Axis Robot

- Leak Tester

- Outfeed Conveyor

- Laser Marker

- Fume Extractor